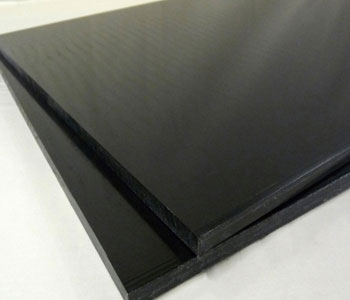

POLYACETAL SHEETS AND RODS

POM Sheets plastic is a semi crystalline thermoplastic with high mechanical strength and rigidity

Due to its low moisture absorption rate, Acetal’s physical properties remain constant in every environment, resulting in an ideally suited and stable product for close tolerance mechanical parts and electrical insulators of Delrin Machined Parts.

A distinction is made between acetal homopolymers (POM-H - mainly manufactured from DuPont Delrin®) and acetal copolymers (POM-C) in regard to their properties. Due to its higher crystallinity, the properties of POM H include a slightly higher density, hardness and strength. POM C material, however, has higher chemical resistance and a lower melting point than POM H.

POM-C rods are appropriate for:

POM-C spring components, bushings, gears, cam disc (eccentric), cam discs and ratchet mechanisms, sliding components, electrical insulators, valves, major precision components, various components and details that work long under water at t ° 60-80 ° C .

Characteristics of Polyacetal

Fatigue endurance unmatched by other plastics

High tensile strength, stiffness and impact strength

Excellent resistance to moisture, gasoline, lubricants, solvents and many other neutral chemicals

Excellent dimensional stability

Resilience and creep resistance

Natural lubricity

Wide end use temperature range

Good machinability

FDA compliant (few grades)

Specification :

| Stock Shape | Colour | Size Range | Dimensions |

|---|---|---|---|

| POM Rods (Round) | Natural (White), Black + 14 Colours | Diameter : 4mm to 300mm | Length : Upto 3000mm |

| POM Rods (Square) | Natural (White) & Black | 25mm x 25mm to 100mm x 100mm | Length : Upto 2000mm |

| POM Sheets | Natural (White) & Black | Thickness : 1mm to 120mm | Width : 620mm/1000mm Length : Upto 3000mm |

Mechanical Properties :

| MECHANICAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

|---|---|---|---|---|

| Tensile strength at yield | 57 | MPa | 50mm/min | DIN EN ISO 527-2 |

| Tensile strength | 57 | MPa | 50mm/min | DIN EN ISO 527-2 |

| Modulus of elasticity (tensile test) |

2900 | MPa | 1mm/min | DIN EN ISO 527-2 |

| Notched impact strength (Charpy) | 4 | kJ/m2 | max. 2J | DIN EN ISO 179-1eA |

| Elongation at break | 15 | % | 50mm/min | DIN EN ISO 527-2 |

| Flexural strength | 82 | MPa | 2mm/min, 10 N | DIN EN ISO 178 |

| Modulus of elasticity (flexural test) |

2700 | MPa | 2mm/min, 10 N | DIN EN ISO 178 |

| Compression strength | 30 | MPa | 1% / 2% | EN ISO 604 |

| Ball indentation hardness | 141 | MPa | ISO 2039-1 | |

| Compression modulus | 2300 | MPa | 5mm/min, 10 N | EN ISO 604 |

| Impact strength (Charpy) | 56 | kJ/m2 | max. 7,5J | DIN EN ISO 179-1eU |

| Elongation at yield | 11 | % | 50mm/min | DIN EN ISO 527-2 |

Thermal Properties

| THERMAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

|---|---|---|---|---|

| Service temperature | 100 | C | long term | NN |

| Service temperature | 140 | C | short term | NN |

| Glass transition temperature | -60 | C | DIN EN ISO 11357 | |

| Melting temperature | 168 | C | DIN EN ISO 11357 |

Electrical Properties

| ELECTRICAL PROPERTIES | VALUE | UNIT | PARAMETER | NORM |

|---|---|---|---|---|

| surface resistivity | 1014 | O | Silver electrode, 23°C, 12% r.h. | DIN IEC 60093 |

| volume resistivity | 1013 | O*cm | Silver electrode, 23°C, 12% r.h. | DIN IEC 60093 |

Features:

- ➽ High impact resistance

- ➽ Excellent vibration resistance

- ➽ Resistance to brittleness and deterioration

- ➽ Easy to machine and fabricate

- ➽ Good abrasion resistance

- ➽ High heat distortion temperature

Applications:

- ➽ mechanical engineering

- ➽ resistant to cleaning agents

- ➽ oil and gas industry

- ➽ aircraft and aerospace technology

- ➽ food technology

- ➽ very good electrical insulation

- ➽ medical technology